Microreactors of the Future for Efficient Wastewater Treatment Using Hydroxyl Radicals

George Becker/Pexels

Date of publication:

The issue of wastewater treatment is becoming increasingly pressing in modern society, which is also reflected in the intensive research in this field. Conventional treatment methods are struggling to keep up with the growing diversity of pollutants that end up in various water bodies – both surface and groundwater. As a result, significant efforts are being invested in developing new technological approaches to address this challenge, with cavitation emerging as one of the promising technologies.

Cavitation is a physical phenomenon in which small vapor bubbles form in a liquid due to a local pressure drop. When these bubbles collapse, strong mechanical forces (shear forces, pressure shock waves, microjets) and chemical reactions are generated, particularly the formation of hydroxyl radicals. These radicals are extremely reactive and can effectively break down organic micropollutants and inactivate bacteria and viruses in water.

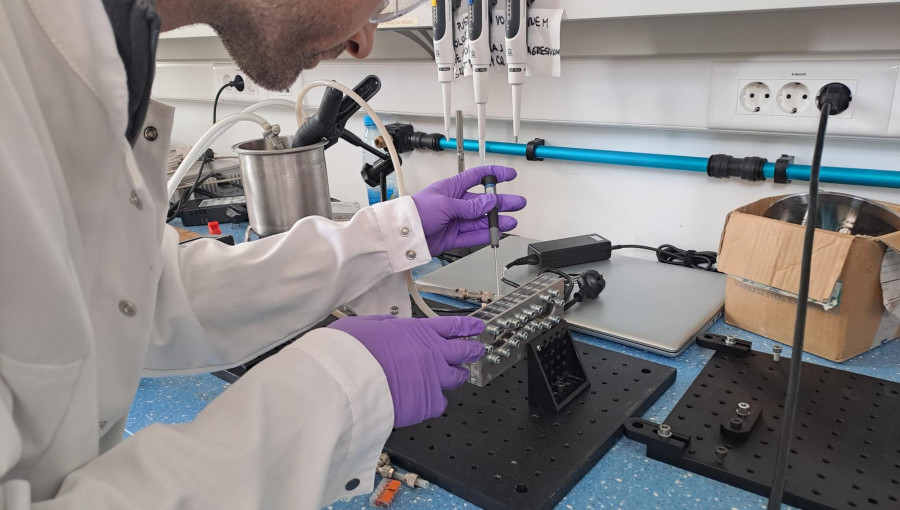

So far, cavitation research has mainly focused on larger reactors with millimeter to centimeter-scale constrictions. In this study, however, researchers from the Faculty of Mechanical Engineering and the Faculty of Pharmacy at the University of Ljubljana, in collaboration with Sabanci University in Istanbul (Turkey), investigated the effects of microfluidic reactors with constriction sizes in the micrometer range. They found that reducing the reactor size significantly alters the characteristics of the cavitation flow – increasing the production of hydroxyl radicals, which accelerates the degradation of micropollutants.

The results show that a properly designed microreactor can enhance chemical effects by up to 30 times compared to traditional systems. This opens new possibilities for more efficient and cost-effective water treatment. “Our findings demonstrate that microfluidic reactors allow for better control of cavitation. This technology can be applied in industry, particularly for water purification,” emphasizes dr. Mojca Zupanc, one of the lead authors of the study.

Looking Ahead

In the future, such microreactors could become key components of compact and energy-efficient devices for water purification, degradation of harmful chemicals, or even material synthesis.