Areas

Environment

Fields of use

Green chemistry and Wastewater treatment

Current state of technology

Pilot scale prototype

Intellectual property

Patent application number: P50434LU00

Developed by

University of Ljubljana, Faculty of Mechanical engineering

Reference

821-16/2020

Contact

Download PDF

- TO-Cavitation-Biodegradability_EN.pdf (pdf, 343 KB)

Background

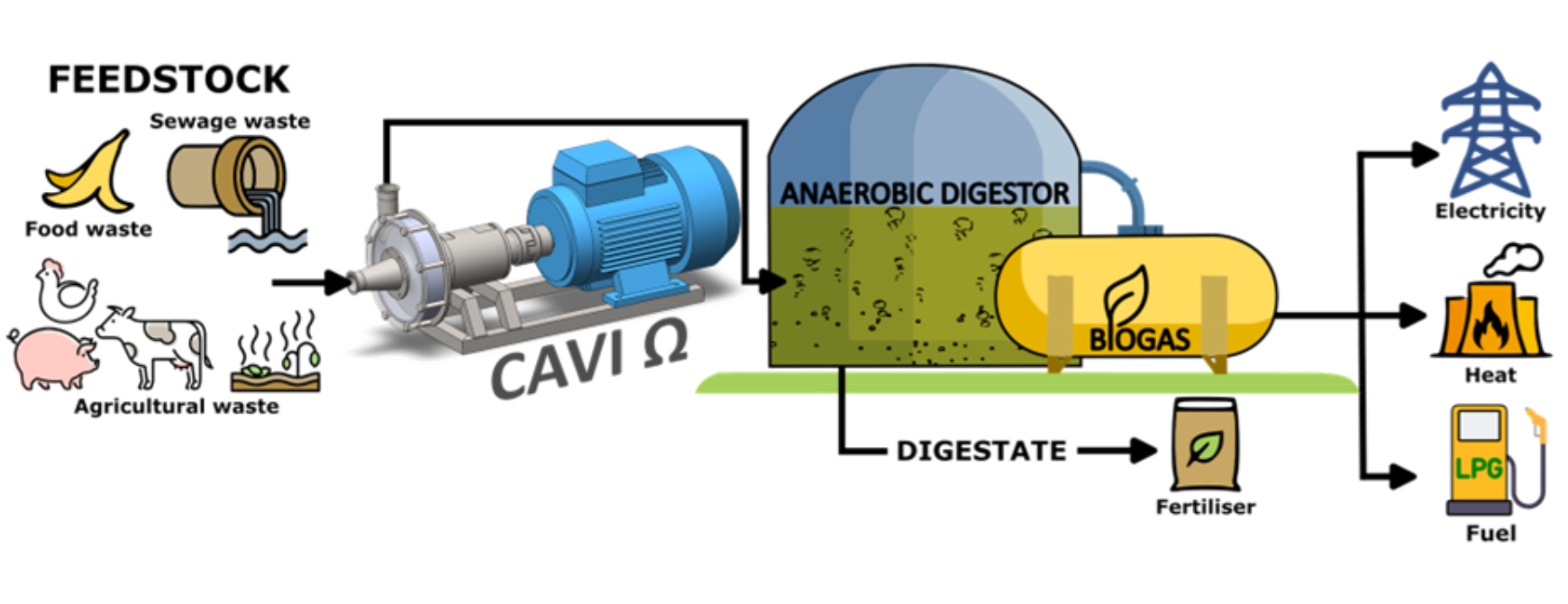

The management of waste streams in processing plants that handle organic materials such as animal waste, dairy products and poultry is usually very energy intensive. Since these organic waste streams are very nutrient-rich, an effective strategy for reducing energy consumption is anaerobic digestion, which converts the nutrients into energy-rich biomethane.

Anaerobic digestion is a biological process in which organic material is broken down in the absence of oxygen. Microorganisms decompose the organic matter and produce methane-rich biogas and nutrient-rich excess sludge as a by-product. In the further course of the process, the suspended fraction of the excess sludge is separated mechanically by dewatering, while the dissolved organic fraction is treated biologically.

The biogas can be used to generate electricity and heat, which can be used within the processing plant, reducing dependence on external energy sources.

However, the efficiency of anaerobic digestion can be limited by the poor biodegradability of waste feedstock such as fats and complex organic materials, resulting in low biomethane yield and high chemical load of the excess liquid content of the reactor.

Description of invention

To improve the process and the conversion of nutrients into biogas and thus increase the biomethane yield while reducing the chemical load of the excess reactor content, we have developed a reactor that utilizes the phenomenon of hydrodynamic cavitation.

Cavitation occurs when vapour bubbles form in a liquid due to a sudden drop in pressure. These cavitation bubbles then burst, and release an immense amount of energy in the form of high pressure (up to 1000 bar) and heat (up to 5000 K). The energy released by the bursting of the bubbles has mechanical, thermal and chemical effects on the surrounding liquid as well as on the dissolved and suspended components.

Our reactor was developed to harness this cavitation energy for the processing of liquids. It is a scalable, modular unit that can be operated as a stand-alone system or integrated into an existing process.

Main advantages

The reactor requires no chemical agents and is powered solely by electricity. Our experiments show that cavitation pretreatment of AD feedstock can significantly improve the biodegradability of AD, resulting in up to 30 % higher biomethane production and a 25 % reduction in the chemical load of the dissolved fraction of the excess sludge.